RPE is a renowned engineering firm specializing in advanced Sludge Dewatering Screw Press Machines, redefining wastewater treatment processes for industries worldwide. Our state-of-the-art machines are engineered to efficiently separate water from sludge, reducing volume and minimizing environmental impact.

RPE’s Sludge Dewatering Screw Press Machines are known for their robust design and exceptional performance, making them a trusted choice for applications in municipal wastewater treatment plants, industrial facilities, and more. With a commitment to sustainability and eco-friendliness, our machines contribute to cleaner and greener water management practices, enhancing operational efficiency while meeting stringent environmental regulations. Choose RPE for cutting-edge solutions that set new benchmarks in sludge dewatering technology, ensuring a cleaner and more sustainable future.

Description

The main purpose of a sludge dewatering machine is to minimize sludge handling and disposal.

Sludge Dewatering Machine reduces the sludge volume and mass by removal of sludge water from interstices between sludge particles. The sludge cake so produced has a moisture content of about 15-25%.

Following features make sludge dewatering , the most effective machine:-

- Suitable for sludge of 0.2%-10% solid consistency at Input and achievable outlet consistency of 15-25% dry

- Our machine can handle a wide flow rate from 0.5m3/hr up to 150m3/hr and sludge concentration from 0.2 to 10% and can easily handle oily/sticky

- Extremely low power consumption( 90-95% less than decanter centrifuge)

Working Principle of Sludge Dewatering Machine:

Dewatering Principle:

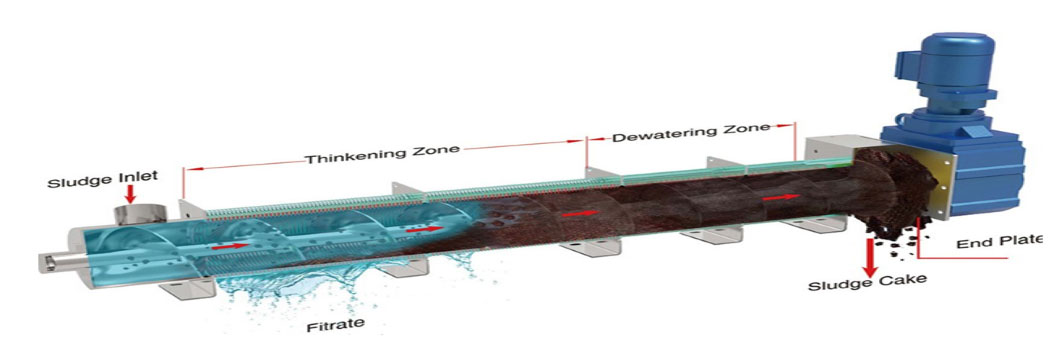

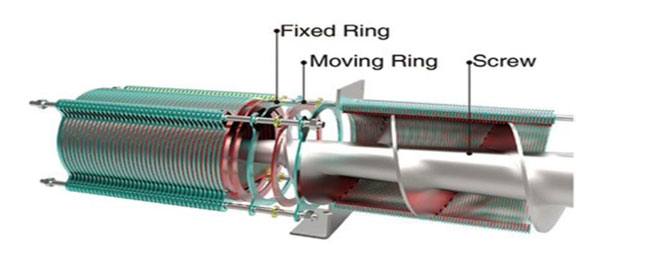

The initial section of dewatering drum is the thickening Zone, where the solid-liquid separating process takes place and where the filtrate will also be discharged. The pitch of the screw and the gap between the rings decrease at the end of dewatering drum, hence increasing its internal pressure, end Plate further increases the pressure, so as to discharge dry sludge cake.

Process Introduction:

Sludge is first flow into the Control Tank and then flows down into the Flocculation Tank, Where polymer coagulant is added.

From there, the flocculated sludge overflows into the dewatering drum where it is filtered and compressed. The entire operation sequence, including sludge feed control, polymer makeup, dosing and sludge cake discharge are controlled by the built-in timer and sensors of the PLC.

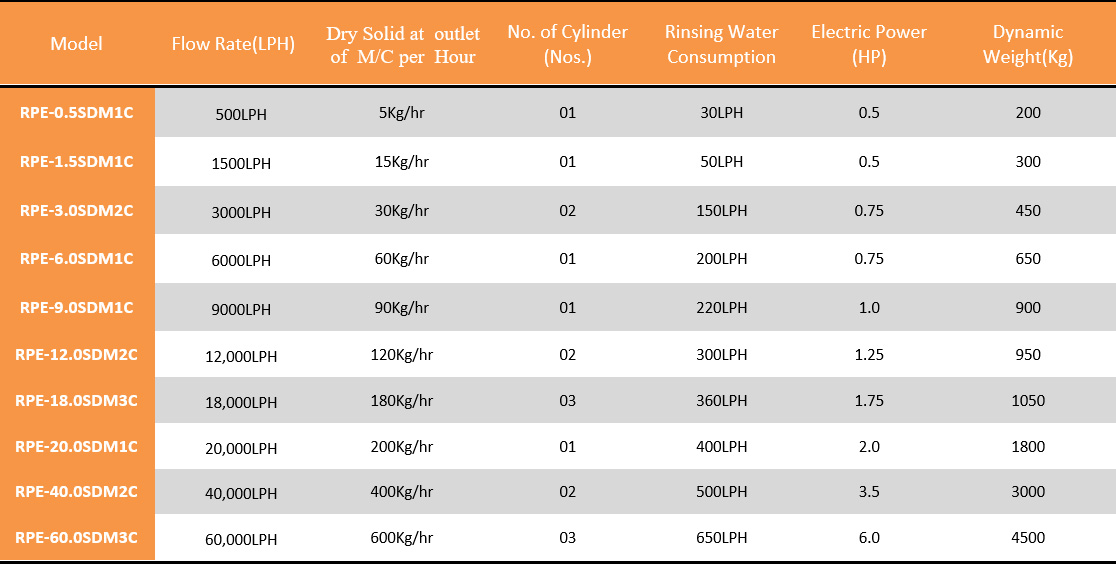

SLUDGE DEWATERING MACHINE MODELS:

Reviews

There are no reviews yet.